How will the products of tomorrow be manufactured? During a MADE session at the Tech Trends of Tomorrow conference, experts from around the world lifted the veil on trends set to reshape manufacturing in the future.

Nigel Edmondson Director, MADE, moderated the MADE session at the Tech Trends of Tomorrow conference.

Nigel Edmondson Director, MADE, moderated the MADE session at the Tech Trends of Tomorrow conference.Will a person or an artificial intelligence (AI) be engineering our products?

Will we be manufacturing remotely rather than on site?

And how will technologies such as additive manufacturing reshape the physical process of industrial production?

At the Tech Trends of Tomorrow conference held by the Danish Ministry of Foreign Affairs, experts from around the globe shared their insights into up-and-coming technologies and trends. At a MADE-hosted session we explored the future of manufacturing.

A huge fat brain

According to Prashanth Gorur Varadaraj from Innovation Centre Denmark (ICDK) in Bangalore, the industrial Internet of Things (IoT), AI and machine learning (ML) are on their rise as it becomes possible to collect more data and tools for analysis become more available. He believe, they will play a key role in shaping tomorrow’s manufacturing.

AI and ML will combined with IoT expand the network, capability and speed of a production’s brain. This makes it possible to make rapid modifications and product customisation. The expanded network of data sources and better tools for analysis deployed with the aid of AI also creates perfect conditions for automating quality control and waste reduction.

For tasks where the factory brain still needs help, software is set to enable increasingly remote operation. Digital replicants – so called digital twins – of the factory will make it possible for blue-collar workers to perform factory-floor tasks from the comfort of their own home.

As Prashanth Gorur Varadaraj puts it in his presentation: “Software is eating the industrial world”.

Moreover, as these software-powered tasks take over, the DNA of the workforce will – according to Prashant – undergo a radical change as the factory environment becomes more appealing to a global, white-collar, gender-neutral workforce.

Presenters at the MADE session on Tomorrow’s Manufacturing

Tim Lüken, Venture Director Additive Manufacturing, TUM Venture Labs

Prashanth Gorur Varadaraj, Head of Tech, Services & Smart Cities, ICDK Bangalore

Line Holm Nedergaard, Innovation Consultant, ICDK Munich

Ulrich Hedegaard Brorson, Group Vice President, Grundfos Holding A/S

Moderator: Nigel Edmondson, Director, MADE

The Global Tech Trend reports

In a series of 20 brief reports trends have been identified and developed by the seven innovation centres that are strategically placed across global innovation hotspots in Silicon Valley, Boston, Munich, Tel Aviv, Seoul, Shanghai, and Bangalore.

The project was mandated by The Danish Government’s Action Plan for Economic Diplomacy, and the underlying ambition has been to answer the question “which areas of technology will come to dominate the future of business, science, and innovation?”

The Global Tech Trends reports are co-published by TechBBQ and Innovation Centre Denmark.

A global network of interacting factories

Taking it one step further: the digital twin and the factory brain do not have to be limited to the four walls of a single factory. They could be linked to other brains and digital twins around the globe, making it possible for different factories across a supply chain to collaborate on a whole new level.

According to the Global Tech Trend reports by the seven ICDK centres, one outcome will be a decrease in downtime:

“Automating logistics, production, and testing on this scale in real time could decrease delivery time and thus downtime at the factory.”

Arms and eyes everywhere

Moving on to the next trend. Not so surprisingly: cobots.

Is it new? No. But the boom in the cobot market will change how SMEs especially manufacture. Cobots are expected to reach in the region of a USD 2 billion market in 2030 especially because “the initial investment in cobots is lower than in traditional robots as you don’t have to change the entire production line and because they don’t need to be fenced off,” Innovation Consultant Line Holm Nedergaard from ICDK Munich explains.

Not only arms but also robotic eyes will increasingly play a role in shaping our products. By 2028, autonomous mobile robots are set to generate a USD 10,517 million market, and one of the reasons why this market can expand is improved machine vision, giving robots the gift of sight. According to Line Holm Nedergaard, the improved vision of autonomous mobile robots as well as cobots should result in greater flexibility, less programming and enhanced quality in manufacturing.

Additive technologies and aerospace

Another not so surprising trend is additive manufacturing (AM) technologies. According to Wohlers Report 2021, the AM market grew – despite the covid pandemic – by USD 12.8 billion compared to 2020.

Moreover, 65 percent of engineering businesses sourced or produced more 3D printed parts in 2020 vs. 2019, according to the AM manufacturing trend report 2021 from HUBS.

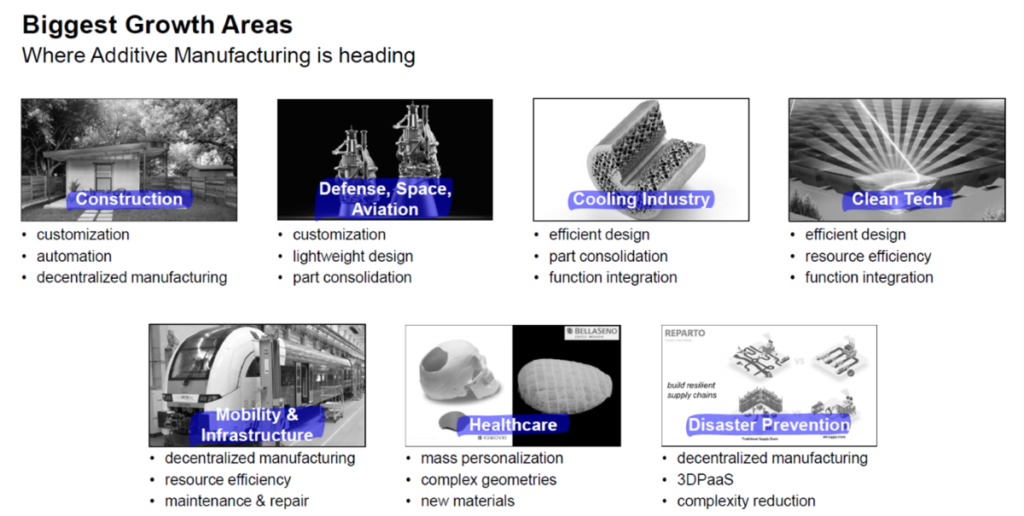

A presenter at the MADE session, Tim Lüken, Venture Director with TUM Venture Lab Additive Manufacturing in Germany, which works with startups in AM technology, explained that AM especially is set to increase in the construction, cooling, clean tech, healthcare, disaster prevention, mobility and infrastructure and, last but not least, aerospace industries.

One of The Global Tech Trend reports from IDC highlights the aerospace industry as driving the growth of 3D-printing.

“Advanced 3D printed parts for space exploration, using lightweight, high-strength materials and printing with minimal waste, are driving the demand for 3D printers in aerospace. Printing on-demand parts in space and 3D-printed large structures are some applications pushing boundaries and driving innovation using this technology,”

Change of roles: the AI engineer

While Tim Lüken outlined the future of AM to the audience in the Danish Ministry of Foreign Affairs conference hall, he highlighted one specific point of interest:

How can AI disrupt the way we 3D-print?

“An AI can faster and more accurately analyze huge amounts of data, and predict how to design a product in an optimal way with the right materials and geometry compared to what a human mind will ever be capable of,” he said during his presentation and added:

“It will completely change how we engineer using AM technology. We will only be programmers, and the AI the engineer and designer”.

An AI-powered AM unit will then be able to create a series of test-ready design variants in minutes. The design and testing process will thus be shortened significantly.

“Instead of the conventional production line, Additive Manufacturing will disrupt engineering and leverage the additive manufacturing potential,” Tim Lüken concluded.

Through the MADE FAST research platform, companies, universities, and GTOs work together to reap the benefits of using new technologies and innovative methods in manufacturing such as those mentioned above.

One of the companies engaged in research and innovation in MADE FAST is Grundfos. Here, the AM technology is, for example, applied in producing tools for use in production, while IoT makes it possible for different products to ‘talk’ to each other.

At the Global Tech Trends Event Group, Vice President Ulrich Hedegaard Brorson explained how Grundfos’ work with innovative technology focuses on fast-track testing and creating measurable impact.