To get a specific part to the robot in the right position is a common challenge when you want a robot to do assembly tasks.

A typical solution to this challenge is to use vibratory feeder bowls. With the help of vibration and custom designed mechanical arrangements such as conveyor chutes, only parts oriented in a particular position will reach the robot.

The problem is, though, that these vibratory feeder bowls are expensive due to the time needed for the development of the individual bowl solution.

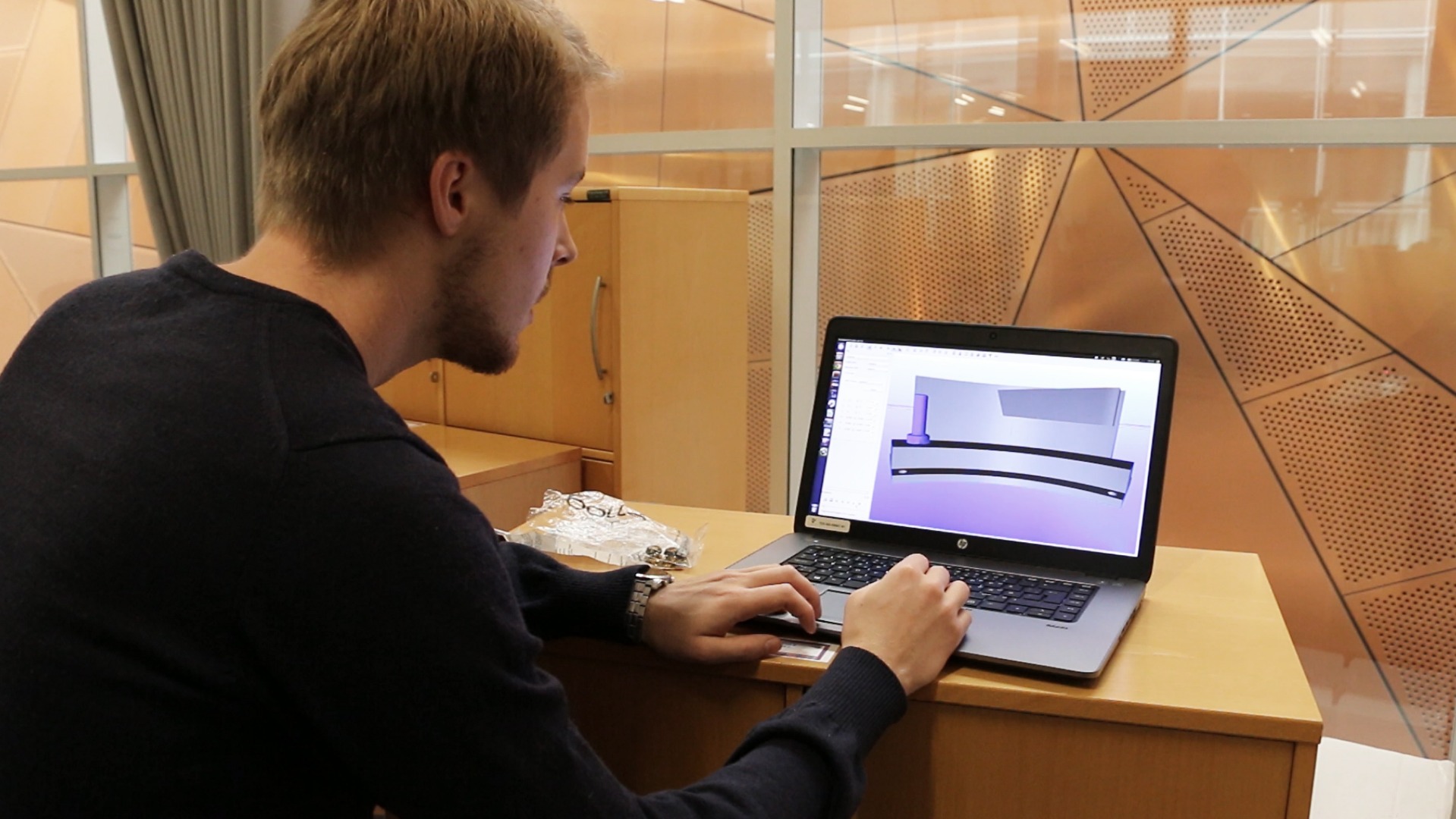

Simon Mathiesen is using advanced computer simulation to deal with this problem. As a postdoc at The Maersk Mc-Kinney Moller Institute at University of Southern Denmark, he is a researcher in MADE within robotics and automation with collaborative robots.

“There is a financial potential if we can use simulation software to speed up the development of these vibratory feeder bowls. This way, the bowls could be cheaper to develop and produce and thereby a less costly investment for the companies in need of a part feeding solution in their production,” Simon Mathiesen says.