With new advanced automation solutions gaining ground in Manufacturing Denmark, demand is growing for more efficient training of employees and new digital tools to support them in solving complex tasks and problems without having to bring in remote experts.

Through the Sustainable and agile workforce initiative, part of the MADE FAST research platform is meeting that demand. In this way, by developing digital assistance tools and learning programmes, we are readying today’s and tomorrow’s workforce to work with state-of-the-art automated, intelligent and digital solutions in advanced manufacturing.

With these tools, industry can overcome challenges regarding the training of new employees and offer their expert knowledge around the world without spending time and money on traveling.

Kaj Grønbæk, Workstream Leader and Professor at Aarhus University

Contact:

Kaj Grønbæk

Professor and leader of the initiative Sustainable and agile workforceMobile: +45 2149 5634

Mail: kgronbak@cs.au.dk

Developing technologies and methodologies

Within the first two development domains, where the focus is on technology R&D and access to applying it in advanced manufacturing, Denmark’s universities, Research Technology Organisations (RTOs) and companies are collaborating closely on proof-of-concept prototypes, etc.

‘The research will ally lab-based state-of-the-art experiments with AR/VR technologies and methods applied to company briefs and challenges,’ explains Kaj Grønbæk, who is the lead on the Sustainable and Agile Workforce initiative and a professor at Aarhus University, adding that this will also entail extensive user involvement through field studies and evaluation with input from company employees.

Grønbæk offers an example of a problem the initiative can assist companies with:

‘An employee at a manufacturing facility overseas might need the support of an expert in Denmark to adapt a casting machine to a new product line. Instead of the expert having to fly out to the overseas facility, the expert can provide their expertise remotely via AR systems,’ says Grønbæk, adding:

‘With these AR/VR-based tools, industry can both overcome the challenges of training new employees and offer their expertise anywhere abroad without having to spend time and money on travelling.’

New digital learning programmes

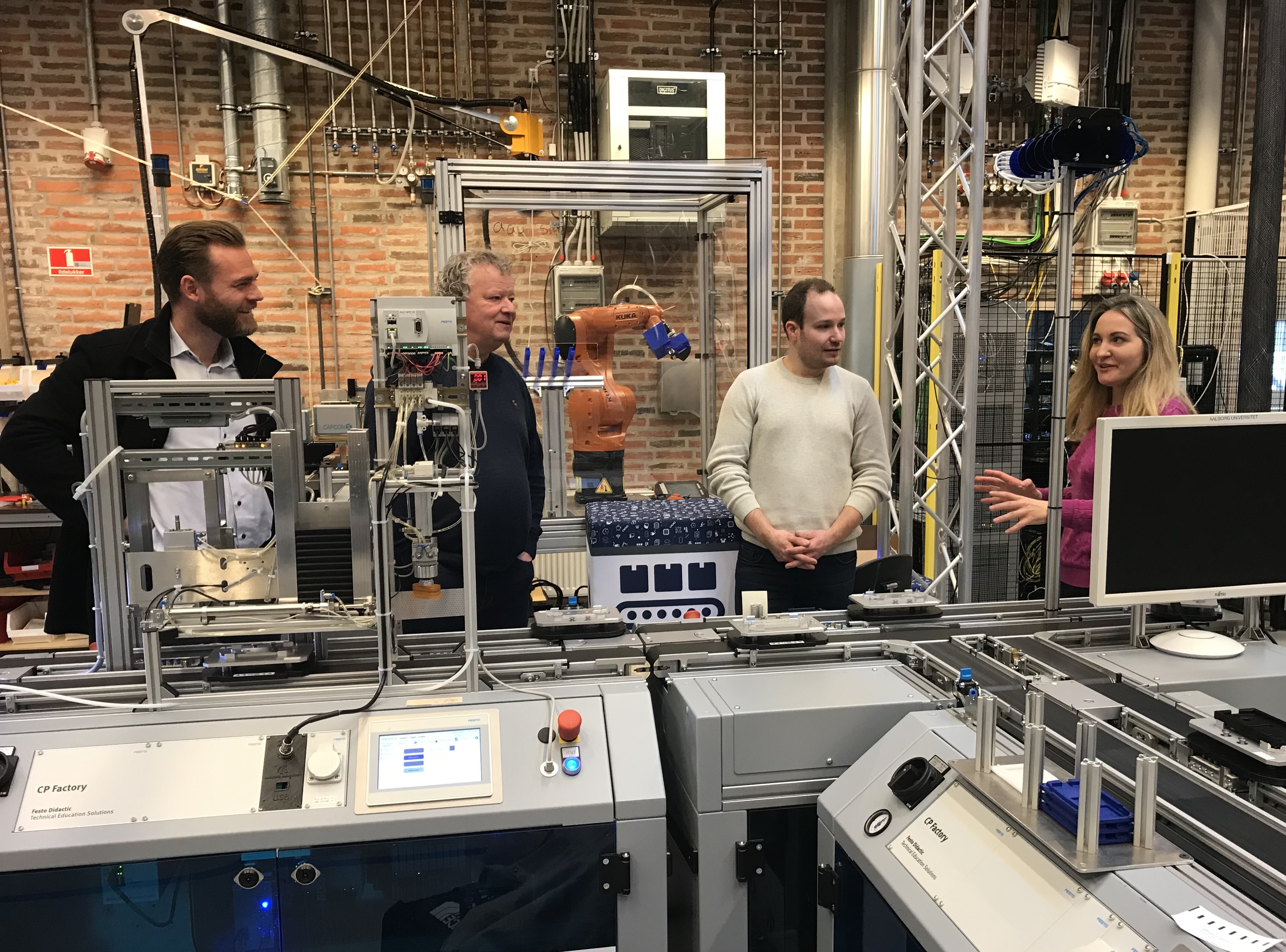

To accelerate adoption of the new digital tools and maximise their potential for upskilling the employees of Danish advanced manufacturing companies, under Sustainable and Agile Workforce, MADE has established three so-called learning factories at Copenhagen School of Design and Technology (KEA), University College of Northern Denmark (UCN) and VIA University College. Collectively, the learning factories go by the name of MADE Learning Factory.

At the learning factories, higher-education institutions, manufacturing companies, knowledge providers and technology suppliers are collaborating mainly on the third development focus of Sustainable and Agile Workforce: devising high-technology learning programmes for employees.

The learning programmes do away with the conventional divide between theory and practice by, for example, being conducted in simulated or live production facility environments. Equally, the programmes focus on applying digital learning technologies to make employee training within advanced manufacturing companies easier, cheaper and faster.

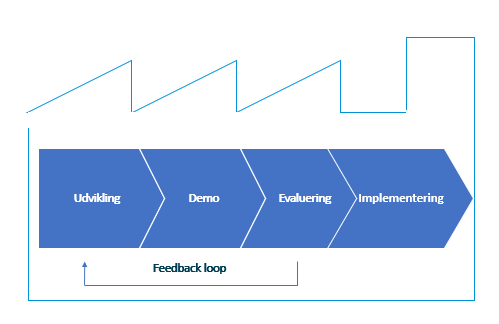

The new digital and flexible learning programmes are created through four phases, as illustrated below.

Thematic heads

- Peter Gorm Larsen, Professor, Aarhus University

- Henrik Gordon Petersen, Professor, University of Southern Denmark

- David Bue Pedersen, Senior Researcher, DTU

- Murat Kulahci, Associate Professor, DTU

- Giuliano Bissacco, Associate Professor DTU

Interested in participating in MADE Learning Factory?

MADE Learning Factory will be developing and testing digital learning programmes until 2024 – and is still open to participants:

- Participate as a programme attendee.

- Participate as an advisory partner for digital learning programme development.

- Participate as an EdTech supplier.

Contact Camilla Nellemann if you would like to join MADE Learning Factory.

Camilla Nellemann

Senior Consultant and responsible for MADE Learning FactoryMobile: +45 60198186

Mail: cnellemann@made.dk

A resilient ecosystem

In Sustainable and Agile Workforce our focus is on synergising manufacturing companies on every scale with suppliers, sub-suppliers, knowledge providers and higher-education institutions in order to promote innovative initiatives (see partners to the initiative below).

One example is the partnership between the LEGO Group, Topsoe and Vestas, all of which have existing VR and AR applications for activities such as training and education, and also use Unity Studios to platform the technology. Within MADE these major corporates are collaborating closely to identify solutions and develop shared tools with SynergyXR (formerly Unity Studios) as their solution provider. The new tools will in turn have applications for other advanced manufacturing companies such as Wexøe.

Aarhus University and Copenhagen Business School are researching how barriers to using the technologies can be overcome, while the Alexandra Institute is assisting by building prototypes and testing them at company facilities.

When it comes to the development of learning programmes based on the new methods and tools, the partner universities are studying digital teaching methods platformed on development of the programme, while a number of educational technology companies (EdTechs), guided by input from companies and higher-education institutions, have the expertise to optimise their solutions to maximise the benefit to Manufacturing Denmark.

An example of this is StudentPulse, which, as an EdTech participant in MADE Learning Factory is developing an analysis tool to optimise learning by assisting employees before, during and after a learning programme.

In other words, help and shared expertise is sourced across industries, organisational scale and form for implementing new solutions in industry and training programmes to benefit all MADE members.

Parties to the initiative

Companies

Boehringer Ingelheim

CAMAR

GN Hearing

Haldor Topsøe

KUKA

LEGO

QualiWare

Stenhøj

StudentPulse

Svanehøj

SynergyXR

Uqualio

Velux

Vestas

VOLA

Wavin

Wexøe

Xcelgo

JKF

Higher-education institutions

AU

CBS

UCN

VIA

KEA

AAU

DTU

Research Technology Organisations (RTOs)

Alexandra Instituttet

Development projects with small-scale enterprises

Under Sustainable and Agile Workforce, the Alexandra Institute, a Research and Technology Organisation (RTO) that helps companies and organisations apply state-of-the-art IT research in practice, will be conducting a number of development projects in partnership with the companies STENHØJ, CAMAR, Xcelgo, EC Power and Wexøe to propose solutions for digital assistance tools and processes.

It may, for example, be time-consuming to train new employees. Beginner’s mistakes may mean costly training. And it may be costly and time-consuming to summon experts for help in repairing machinery. To address this, Danish One2Feed and MADE jointly developed an AR solution, which intuitively and visually guides customers on the other side of the globe in installing and troubleshooting the company’s automated dairy farm feeding system.

SynergyXR (formerly Unity Studios), which creates state-of-the-art virtual reality and augmented reality solutions, will also be developing training and education concepts based on the new technologies to provide a platform for efficient manufacturing machine operator training worldwide. This SME is hoping to halve costs by minimising the time it takes to train machine operators.

Participate in MADE research

Companies and researchers have the opportunity to participate in creating new knowledge and technology within MADE, for example, by partnering with small-scale enterprises on development projects.

Contact us to learn about our open calls for participating in ongoing research projects or get help to secure financing for new research projects in association with MADE.

MADE Mini Course: How to digitalise peer-to-peer training

Get knowledge of digital learning technologies and learn how to digitalise peer-to-peer training.

Kaj Grønbæk

Professor and leader of the initiative Sustainable and agile workforceMobile: +45 2149 5634

Mail: kgronbak@cs.au.dk

Camilla Nellemann

Senior Consultant and responsible for MADE Learning FactoryMobile: +45 60198186

Mail: cnellemann@made.dk