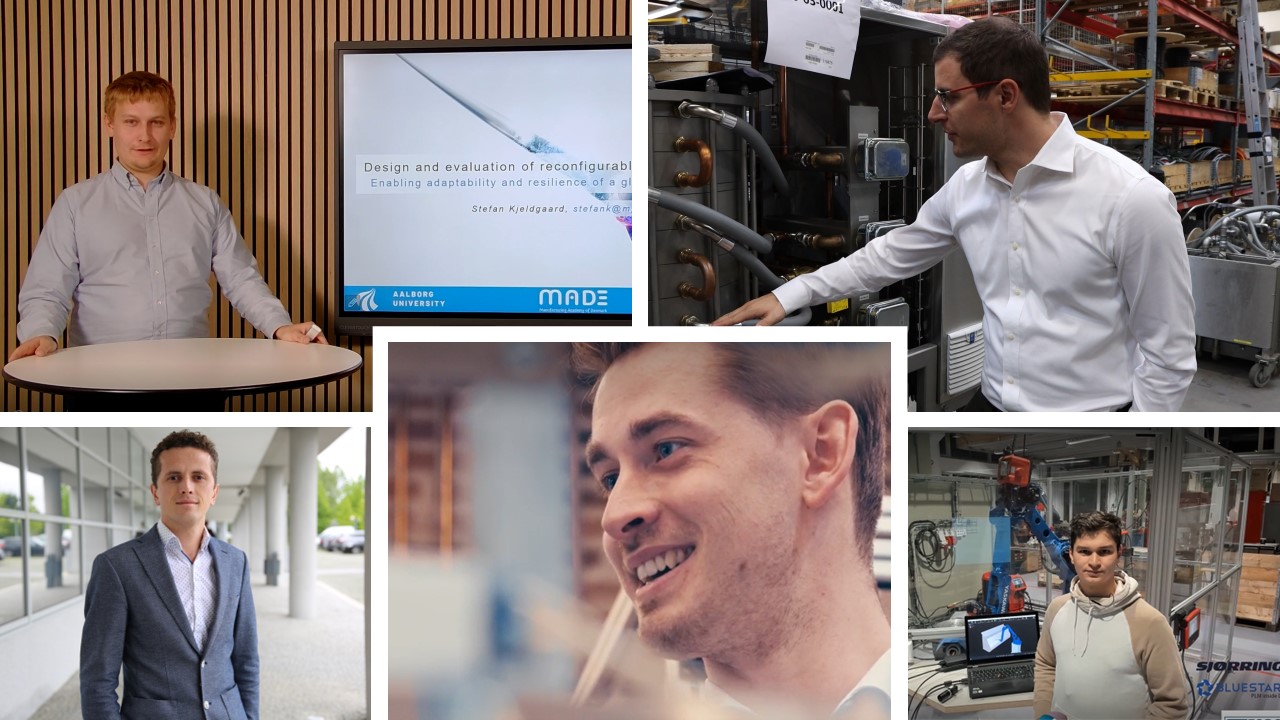

Five MADE researchers are nominated for The Otto Mønsted Foundation's MADE Award 2022. Learn about their groundbreaking ideas that solves or has the potential to solve industrial challenges.

First prize winner is Ioan-Matei Sarivan, Aalborg University and the second prize winner is David Sarancic, DTU

First prize winner is Ioan-Matei Sarivan, Aalborg University and the second prize winner is David Sarancic, DTUThe winners will be announced on stage at the annual MADE event on November 1st..

Here you will be introduced to all five nominees in random order:

1) Emre Yildiz – Aalborg University

MADE Ph.D. at Aalborg University, department of Materials and Production together with Vestas Wind Systems A/S.

Title: Virtual Factory – A systematic approach to building smart factories

Emre Yildiz is nominated for designing and developing a virtual factory demonstrator that makes it easier and faster to design and plan the engineering of a factory in collaboration with Vestas Wind Systems A/S.

The Virtual Factory concept has great potential for fast-evolving enterprises like wind turbine generator manufacturers.

Read more about his research and the potential here.

The PhD work proved its value in several industrial cases by demonstrations to industry experts at production plants. Decreasing time, complexity and physical builds by virtual prototyping, efficient and accurate engineering on process, layout, facility and production system design could be listed some of the primary outcomes of the demo.

Simon Saandvig Storbjerg Director, Head of Vestas PLM Development

2) David Sarancic – Technical University of Denmark

MADE Ph.d. at DTU – Technical University of Denmark together with Aasted and FORCE Technology

Title: Configuration of Technology to Support Sustainable Product-Service System (PSS) Offerings

David Sarancic is nominated for developing new business models for product service systems (PSS) in Aasted. His research has yielded a tool to screen PSS concepts.

David’s project takes a very novel approach to implementing sustainability in an SME utilizing digitalization and the development of a service based new business model.

The project addresses the complexity in delivering sustainable manufacturing solutions and provides tools and dashboards which can be of benefit to the wider industry.

Watch a video about David’s Ph.d. project with Aasted.

David contributes greatly to our company and corporate strategy by introducing a systematic framework to assist us in a common understanding of our potentials regarding the formulation of value proposition alternatives and assess the sustainable value potential of different PSS solutions.

Henrik Heitmann, COO Aasted

3) Ioan-Matei Sarivan – Aalborg University

MADE Ph.D. at Aalborg University together with Sjørring Maskinfabrik A/S, PDM Technology A/S and FORCE Technology

Title: Automatic programming of welding robots based on product-process-resource data

Ioan-Matei Sarivan is nominated for optimizing the value chain execution at Sjørring Maskinfabrik. He has successfully developed proof of concept on a fast welding robot program that increases utilization of resources.

The project has involved all partners in the value chain; suppliers, customers and RTO’s in order to solve a difficult challenge and ensure a sustainable long term ownership of the solution and its future development.

Matei’s approach, research and succesful proof of concept has proved that technological solutions will boost our competitiveness through reduced cost and a faster time to market. Both are essential parameters of competitiveness in the field.

CEO i Sjørring Maskinfabrik, Klaus Kalstrup

4) Stefan Kjeldgaard – Aalborg University

MADE Ph.d. at Aalborg University together with Vestas Wind Systems A/S

Title: Design and Evaluation of Reconfigurable Production Systems: Enabling Adaptability and Resilience of a Global Production Network.

Stefan Kjeldgaard is nominated for designing a reconfigurable concept for large-scale production equipment with improved reusability and changeover time.

Stefan’s research supports us in the investigation of opportunities to change the traditional manufacturing approach within our field – regarding a focus on boosting our competitiveness in our supply chains.

Senior Specialist Mads Bejlegaard, CLM Quality Improvements and Processes, Business Unit Power Solutions, Vestas Wind Systems A/S

5) Steffen Foldager Jensen – Aalborg University

MADE Ph.d. at Aalborg University together with Danfoss and Grundfos

Title: Instigating the Circular Transition: Developing product take-back systems of mechatronic devices

Steffen Foldager Jensen is nominated for his research on possibilities and barriers for take back programs. He has explored the potential for takeback and remanufacture of Danfoss products after end-of-life.

We have in Danfoss great expectations to this takeback project, which is central for our efforts towards a more circular business. This project is part of our sustainability ambition and roadmap, where we have set the target that more than 80% of our newly developed products will be covered by the circularity approach by 2030.

Senior Director Sustainability, Compliance & Industry Affairs, Mikael Wassermann, Danfoss

The Otto Mønsted Foundation’s MADE Award

The award will be presented to a Ph.D. student or Postdoc working with one of the five Danish universities (AAU, AU, CBS, DTU and SDU) in MADE.

The winner is announced on November 1st, 2022, at the annual MADE event at Grundfos.

The first prize winner will receive 100,000 DKK and the second prize winner will receive 50,000 and both prize winners will receive a diploma and an art price. The award is sponsored by the Otto Mønsted Foundation, whose main objective is to contribute to the development of Denmark’s trade and industry.