This online seminar from ATV-SEMAPP addresses overall trends in Danish Industri related to issues like pandemics, geopolitical crises and shortage of specific materials and components.

- 6 Dec2022

This text is copied from ATV-SEMAPP's website.

Pandemics, geopolitical crises and shortage of specific materials and components seem to have become normal boundary conditions for industrial companies today. As a company you have to navigate in these complex surroundings and at the same time you need to make sure to be able to run your production and sell your products.

This online seminar addresses some of these issues and illustrates by examples some of the considerations that need to be made in companies. Hear about getting robust and resilient, also with respect to your employees and competencies. And learn about the overall trends in Danish industry related to this topic.

Program

09:00

Welcome and introduction

09:05

How can data help you become robust?

Charles Møller, Professor, Dept. Materials and Production, Aalborg University

Manufacturing companies are facing a myriad of disturbances in today’s global business environment. Green transition, wars, pandemics, logistics disruptions, material shortages, and price volatility, just to mention a few of these. These issues are poisonous to any efficient and optimized operation and many companies are re-organizing their supply chains to better meet these challenges. In this presentation, we will look into how data can help you to become more robust, and also look at the implications to existing enterprise systems and business processes.

09:40

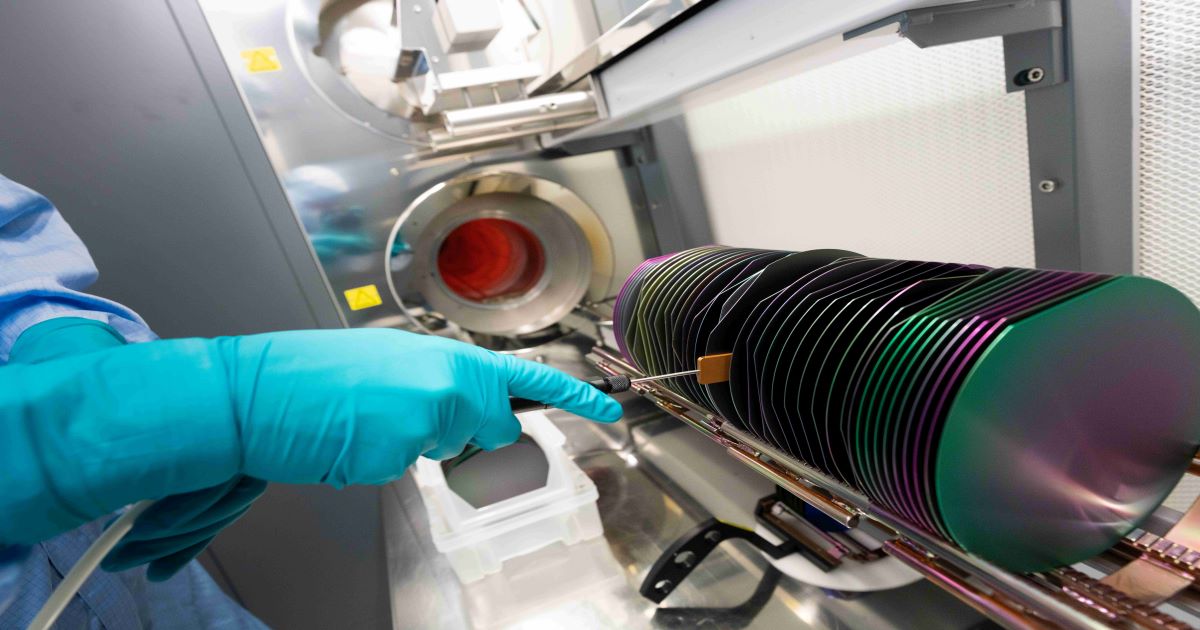

Chip manufacturing – how complexity prevents sovereignty

Jörg Hübner, PhD, Director, DTU Nanolab

Triggered by the chip shortage and the general geopolitical situation EU, US, China, Japan and many other countries try to onshore chip production with an aim of technological sovereignty. A look, not too deep, into the industry reveals that the aim might be out of reach for any country or even continent. From a general view into the chip industry and the complexity of its supply chains we extrapolate on the chances of technological sovereignty and the future of the chip crises.

10:15

Break

10:30

How to transfer Plastic Makers education around the world

Christoffer Høvsgaard,Senior Manager, Moulding Academy, Lego A/S

To move competences around the word can be a challenge, especially when it is core competences in a company. In Denmark we have a great education system, and we are used to that we can hire educated employees with the right basic knowledge when, but when we go to Mexico, China, or Hungary, it is more difficult to secure that the basic knowledge is in place. In this presentation Christoffer will tell about how the LEGO Group has made a local Plastic Maker education in one year, in Mexico, China and Hungary and how we have started this up during Corona time when traveling was impossible.

11:05

Danish manufacturing companies are diversifying and expanding their way to less risk and uncertainty

Morten Granzau Nielsen, Director Economics and Politics, Confederation of Danish Industries (DI)

After two years with large and comprehensive disruptions in international trade, more than 8 out of 10 manufacturing companies have made changes to their strategies. The solution is more globalization, not less. Many companies want to increase the number of suppliers and expand sales to more countries while few choose to re-shore or sell to fewer countries. But the focus is shifting away from China and other politically challenging countries.