Unlock the potential of your CAD-models and offline programming systems for welding robots and achieve a faster lead time in one-of-a-kind production.

- 11 dec2023

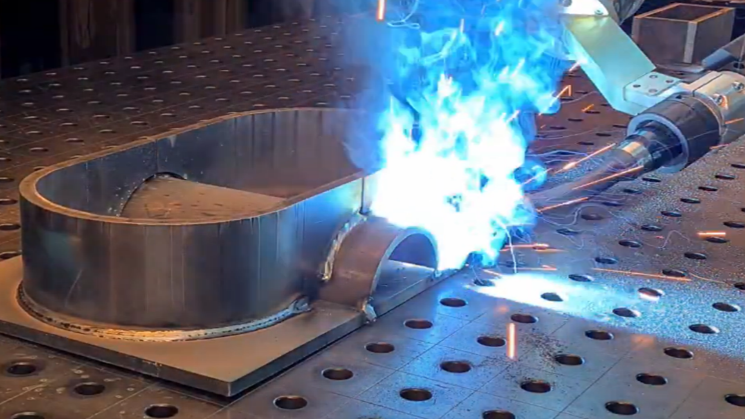

Digital integration of engineering and welding-robot programming

Companies with one-of-a-kind production refrain from using robotics because on average, it takes a few hours to one week to program welding robots.

And that is just by manually re-digitalizing data already available on configurable CAD models as stipulated by the ISO 2553 standard. Novel software can fill the gap between CAD software and offline programming software enabling fast programming of welding robots.

The programming time for welding robots can therefore be reduced to just a few minutes.

By automating the programming of welding robots, time to market can be improved, and redundancy across the valuechain eliminated to optimise usage of skilled labour.

A success MADE story – Sjørring in front

Going through a strategic change towards flexible automation, Sjørring is one of the beneficiaries of novel digital solutions for operations-technology integration across the value chain.

On this Deep Dive, Sjørring will show their automatic configuration of CAD models, developed in a MADE project, and how they use them for automatic programming of welding robots.

Valk Welding – The artificial intelligence behind automatic robot programming

Valk Welding is one of the leading welding-robot technology suppliers. Learn about their use of AI to program Panasonic robots and use of smart sensing for even faster and more accurate welding-robot programming.

Dato

11 december 2023 kl. 10:00 - 11:45

Sted

Microsoft Teams

Sprog

Dansk og engelsk

Tilmeldingsfrist

6 december 2023

Michele Colli, Tlf: +4543251400, E-mail: mic@forcetechnology.com

Program

10:00 Welcome and introduction

Senior Consultant Sandrina Lohse-Larsen, MADE

10:10 Automatic programming of welding robots

Specialist Ioan-Matei Sarivan, FORCE Technology

Automatic programming of welding robots directly from CAD models. How to use digital

technologies for successful value chain optimization and reduce redundancies and how a solution for one company can be scaled to the level of the Danish industry.

10:40 A success MADE story – Sjørring in front

Project Manager Supply Chain & Construction Morten Bojer Hvass, Sjørring Maskinfabrik A/S

Sjørring Maskinfabrik presents a configurated solution powered by DriveWorks with weldments in a 3D CAD model, which was developed in a MADE FAST research project. The method reduces time for construction and design and makes it possible for other systems to gather information about the welding’s position, type, and size, e.g., welding-robot programming.

11:10 Valk Welding – The artificial intelligence behind automatic robot programming

Offline Programming Specialist James de Villiers, Valk Welding

Valk Welding will present an Automatic Robot Programming solution called ARP Powered by ArNC for Panasonic which harnesses the power of machine learning to automate the welding robot programming process. Weld definitions inside the CAD file are used to further increase the level of automation.

11:40 Wrap-up and Closing

Senior Consultant Sandrina Lohse-Larsen, MADE