The world’s largest manufacturer of toys, The LEGO Group, wants to harness and invest in new knowledge from universities to develop skills, tools and factories of the future. At the MADE Innovation Conference participants got an insight into how they successfully have planted seeds in the form of collaborations with DTU and other industrial partners.

MADE’s Managing Director, Nigel Edmondson moderated the event at DTU.

MADE’s Managing Director, Nigel Edmondson moderated the event at DTU.How can we use 3D printing and AM to make the route from concept to mass production as fast and flexible as possible?

This question is central to the close, long-term, interdisciplinary collaboration between the LEGO Group and DTU at MADE, that was presented at the MADE Innovation Conference Join forces with others and come up with ideas and solutions.

”Participants learned how DTU and The LEGO Group have through applied research, innovation and collaboration found solutions to challenges in production – and explored new possibilities within advanced manufacturing ” explains Managing Director Nigel Edmondson.

The secret to success is to balance the long-term and the short-term goals of industry and the university:

“As a university we need to understand that research has to applied in the companies. On the other hand, companies should not view university research as a consultancy service with specific deliverables, and that the development of new technology takes time and collaboration,” says Professor Hans Nørgaard Hansen, PhD, Head of Department, DTU.

Innovation that is needed for the future

The LEGO Group have been a part of every MADE research and innovation platform; MADE SPIR (2014-2017), MADE Digital (2017-2020) and now MADE FAST (2020-2024) where they have developed new 3D-print and Industry 4.0-solutions.

They invest long-term in the belief, that together it is possible to build tomorrow, what we can’t build today.

“We want to grow brain power from the universities, thereby together we can achieve the innovation that is needed for the future. We need collaboration. The door is open. We need you guys – come on,” says Per Høvsgaard, Director R&D, The LEGO Group, that wants to invite other to share knowledge and be part of an open innovation adventure where the journey is equally important as the destination.

At the innovation conference the LEGO Group and DTU explained how they have collaborated to print a plastic insert for injection moulding to replace traditional metal tooling requiring milling and polishing, enabling them to proceed from design to production in a few hours rather than several weeks or even months.

”The key to a great collaboration is to be curious on each other’s skills and challenges and it requires continuous dialogue about how everyone can contribute,” says Professor Hans Nørgaard Hansen.

The Danish manufacturing industry benefits from all the hard work from MADE PhD’s – and currently the LEGO Group has four MADE PhD’s working with one common goal: To understand and improve 3D-print:

80 percent of the MADE PhD’s get hired by companies and 20 percent are hired by the universities on completion of their Ph.D. or Postdoc projects

Nigel Edmondson, MADE’s managing director

”80 percent of the MADE PhD’s get hired by companies and 20 percent are hired by the universities on completion of their Ph.D. or Postdoc projects. Skills and knowledge about digital manufacturing is in great demand and required to digitalize production. It is very important that companies gain access to and quickly absorb new knowledge,” MADE’s managing director underlines.

Brand new AM lab

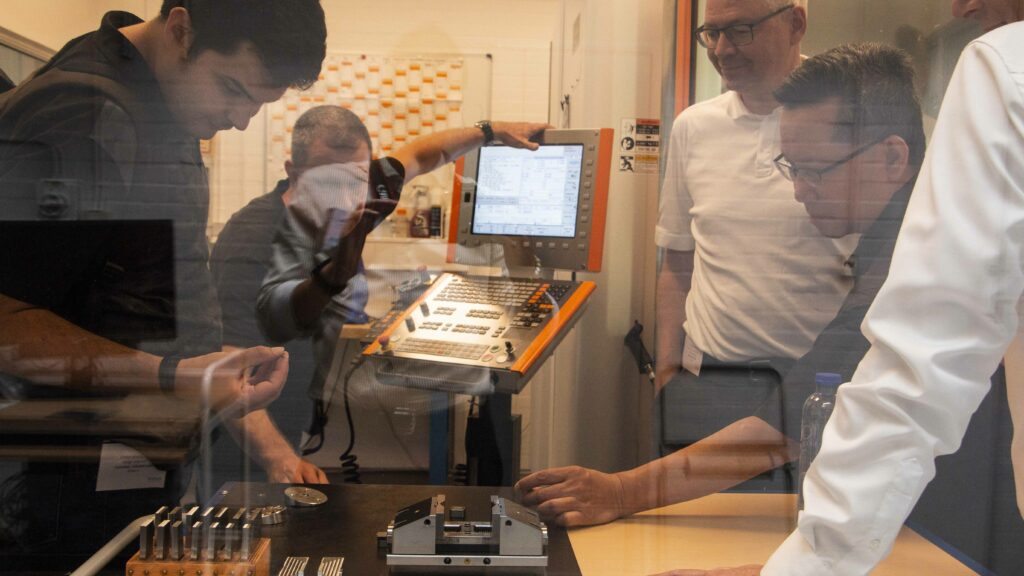

At the MADE Innovation Conference participants explored the brand new AM-laboratorie at DTU and how 3D printing of polymer tools for the manufacturing process adds huge value.

The guided tour in the different labs showcased different 3D printed components like hearing aids in plastic and complex geometry in metal.

It was really great to show all of our new facilities and to tell participants about the exciting research and education that we practice

Hans Nørgaard Hansen, Professor PhD, Head of Department, DTU